IP-400A Perfect Binder

IP-400A Perfect Binder

Description

IP-400A Perfect Binder - The perfect binding solution

Designed and manufactured in Italy, the IP-400A is a new perfect binder that will increase automation and productivity for the short, medium and longer run requirements. The IP-400A meets the rapidly growing demand for quality and professional bound documents and books where quick turnaround and ease of operation are essential.

Product Features:

· Automated cover feeding

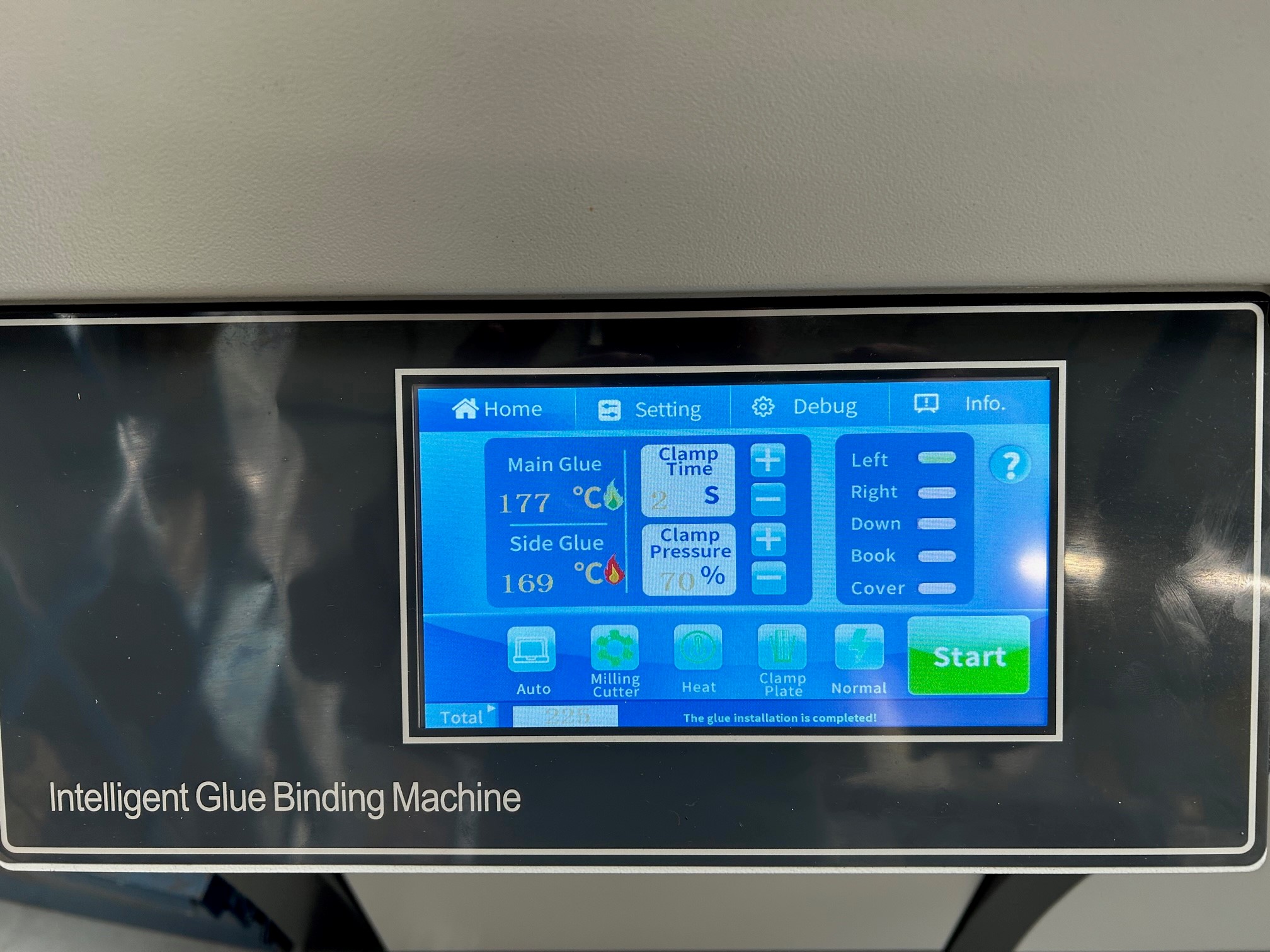

· Colour touchscreen control

· Automatic bound book ejection

· Milling & notching spine preparation

· Spine and side gluing

· Adjustable clamp pressure

· Paper dust extractor

· Fast warm up time

· 320 cycles per hour

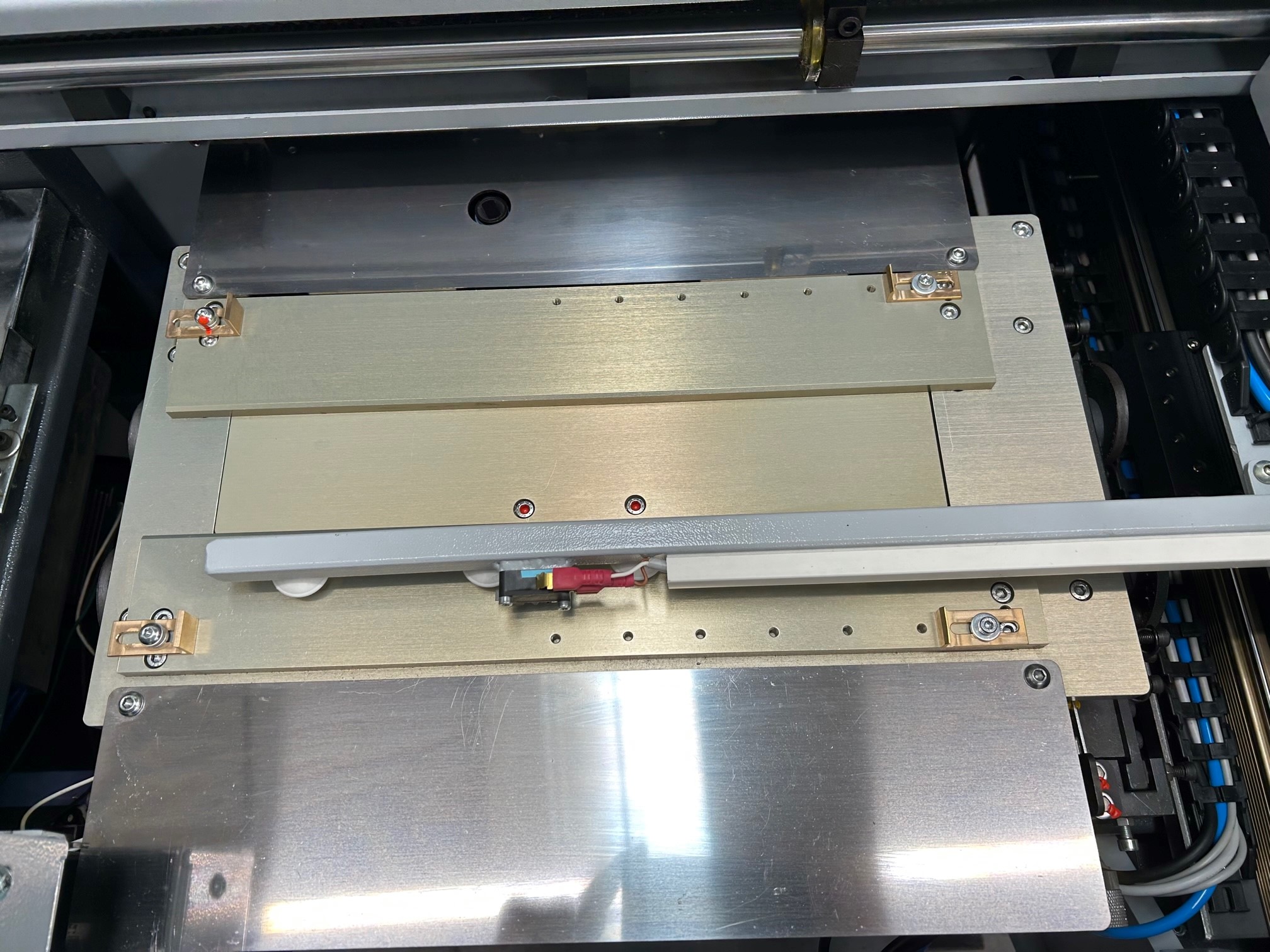

The unique features of the IP-400A are the automated cover feeder and book throw out. Covers, between 120gsm - 400gsm, are automatically feed to the clamp station for book binding before the book block leaves the start position. The feeder uses a suction system, the same as used on top of the range print presses, which is highly accurate and includes the benefit of missing cover cut off. The operator only needs to load the book and the binding process from that point is automated. Once complete the perfect bound books are released from the clamp into the book slide for collection. This brings a huge improvement in automation and a reduction in operator production time.

Operation of the IP-400A is with two touchscreen control panels. The first touchscreen controls the binder setting for glue temperatures, clamp pressure and speed, the second control operates the cover feeder, set up time is a matter of seconds. These two touchscreens offer a level of automation not seen in a perfect binder at this level before. No skilled operator use is required, only minimal training is required to start production.

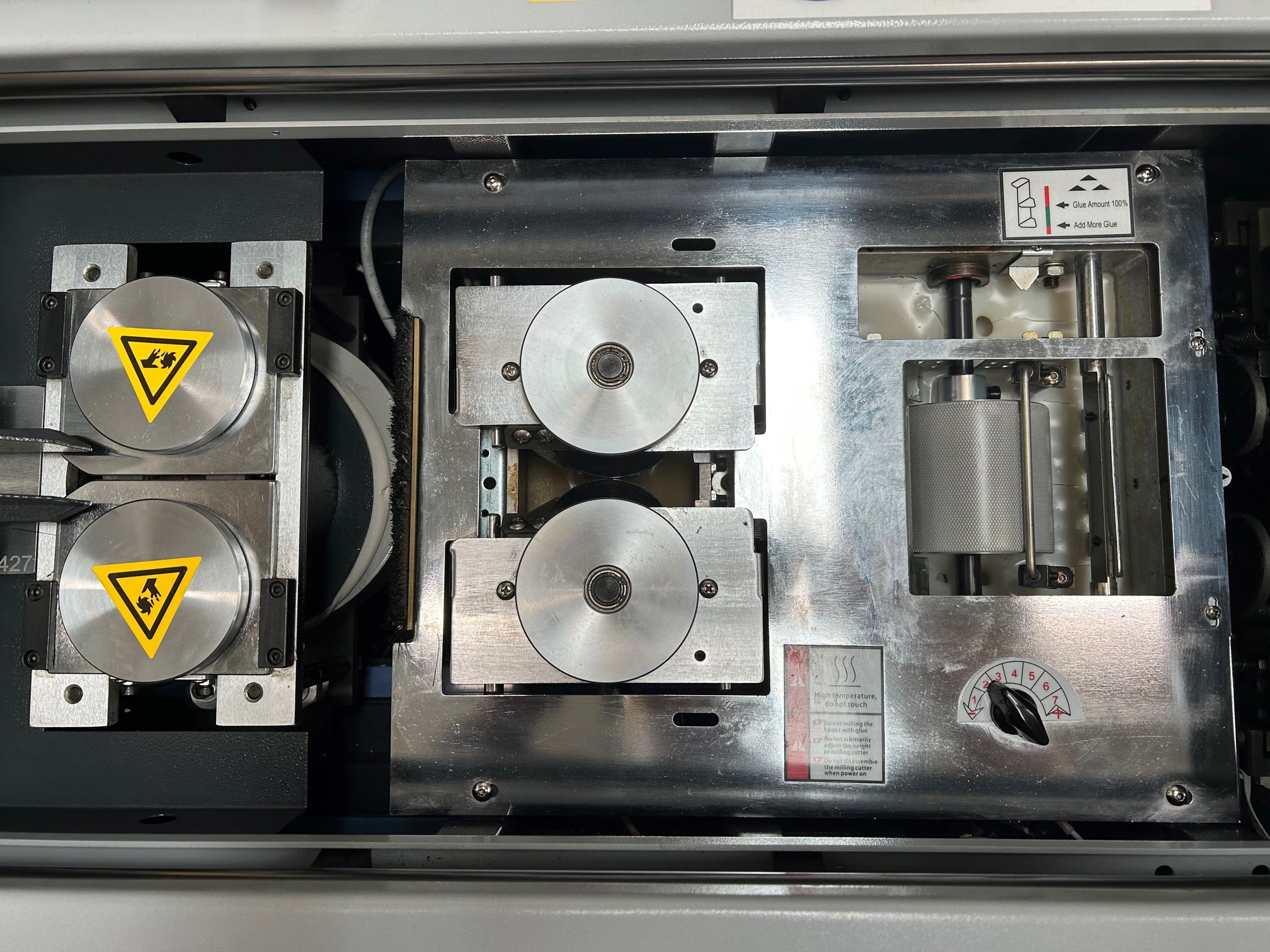

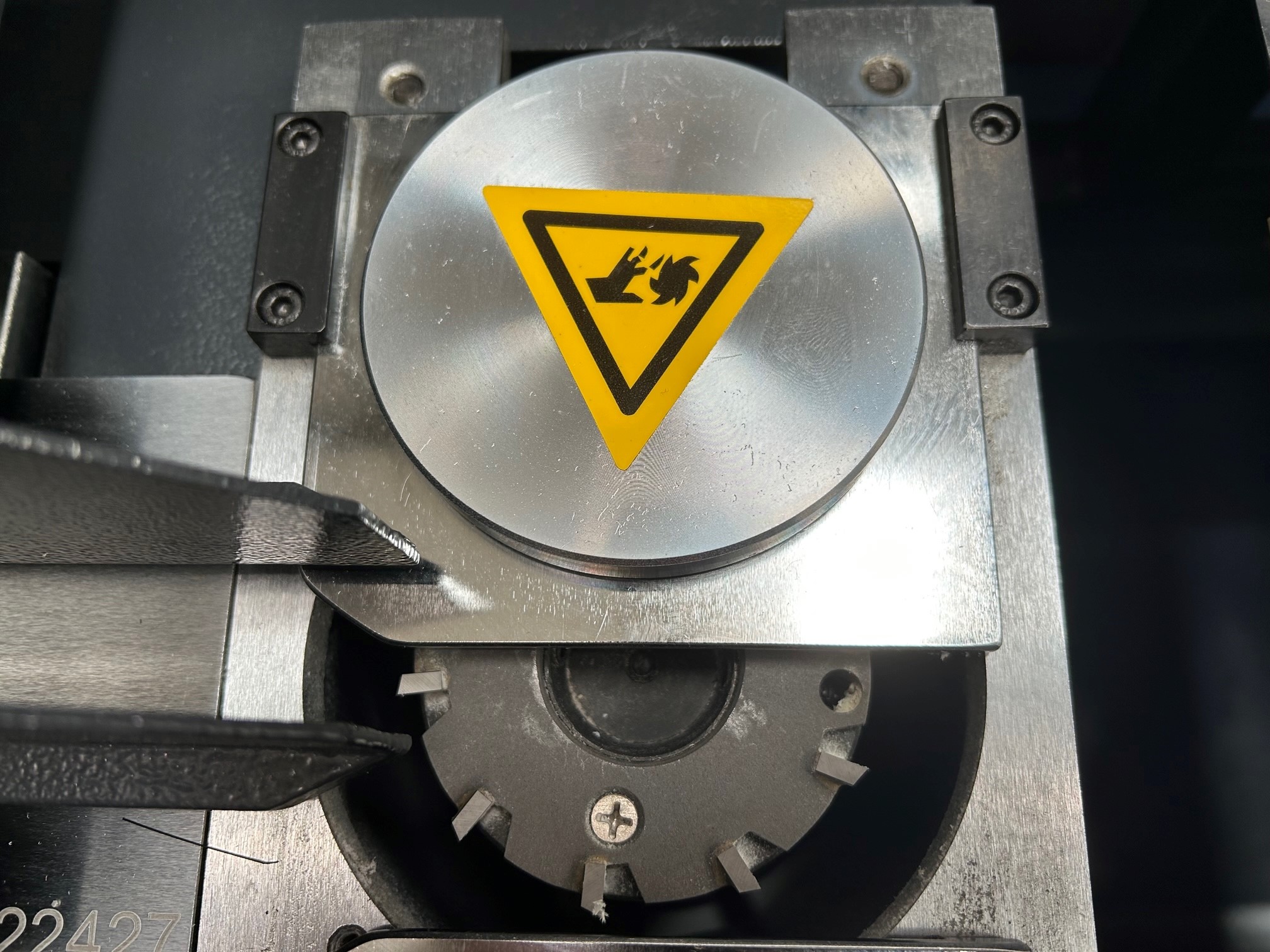

Spine preparation on the IP-400A is via the extra durable milling and notching disc. Before any glue is applied to the spine the book block passes over the disc and a combination of larger notching blades with smaller milling blades break up the paper fibre on the book spine. This process allows for superior glue penetration of the sheets which in turn improves the quality of the bind strength.

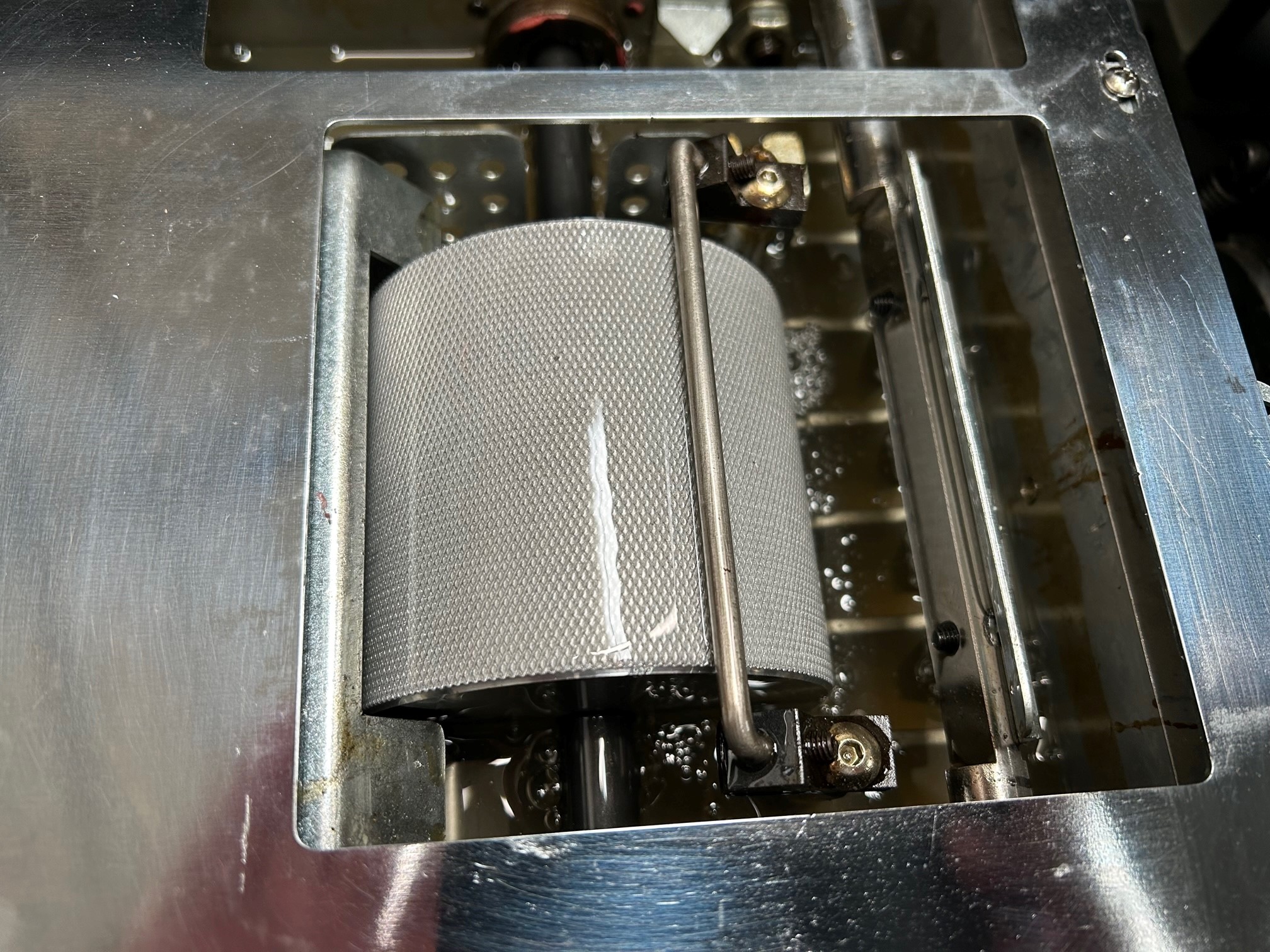

The IP-400A accommodates twin glue tanks for spine and side application. This allows different types of glue to be used for implementation. A stronger glue may be used in the spine tank for better bind results, this may take longer to cure than a standard glue that may be used for spine requirements. However, the more vigorous glue for both spine and side gluing can also be used to simplify the procedure.

The clamping station on the IP-400A has adjustable pressure. Not all books require the same clamp pressure, books can be underly or overly clamped which will affect the quality of the square on the bound spine. This isn’t an issue on the IP-400A. It's possible to reduce or increase, depending on the requirement, the pressure applied to the spine to negate any issues with book clamping problems.

Included with the IP-400A is a paper dust extractor. Paper dust particles can build up in perfect binders during spine preparation, this happens when the milling and notching of the paper fibres take place. This dust extractor works during the milling process and paper particles are stored in a cloth bag helping to reduce any build up of paper in the binder. Often this is an additional cost on binders, it’s a standard feature of the IP-400A.

Specifications

| Manufacturer | Glendale |

| Model | IP-400A Perfect Binder |

| Condition | New |

| Cover Feeder | Suction feed 120-400gsm |

| Missing cover detection | Yes |

| Book ejection from clamp | Automatic |

| Spine width | 2mm-55mm |

| Minimum cover Size | 297 x 130mm |

| Maximum cover size | 500 x 320mm |

| Book height | 110-270mm |

| Separate spine & side glue tanks | Yes |

| Cycle speed | 320 per hour |

| Production speed | 280 per hour |

| Book preparation | Milling & notching disc |

| Paper dust extractor | Included |

| Electrical requirements | 220-240v 50/60Hz |

| Machine weight | 320kg |

| Dimensions | (L)1750mm x (W)1250mm x (H)1130mm |