Troubleshooting: Wire Binding Machines

Common wire binding issues and how to solve them

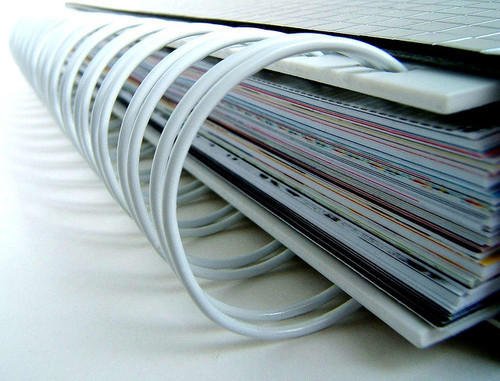

Wire binding is a wonderful way to produce immaculately bound documents which give the best impression of your business and sets both yourself and the document apart from others. High quality binding machines make the entire binding process seamless and easy, but issues arise with even the best machines and most effortless of processes. We have constructed a short list of simple, yet common issues which may come about when using wire binding machines. These issues are not difficult to solve but identifying their cause is sometimes problematic. This guide offers some simple solutions to your problems and identifies the cause of the issue, so you can return to creating amazing bound documents.

Difficulty Opening Document and Turning Pages

If you are experiencing difficulty opening a document or find that the pages won’t turn, once it has been bound, you have likely encountered one of two issues; the spine you have used is too small or the wire has been closed too much. In the case of the former simply purchasing wire binding spines of the correct diameter will remedy the issue. If the issue concerns the spine being closed too much, then you can make the relevant adjustments to your machine. If you are unsure how to make these adjustments, you should be able to find the information for your specific binding machine in the user manuals which came with the product.

Crooked Punching

If your hole punching is crooked there is a possibility that there is some punched paper stuck in the punch. Check the punch pins for paper and make sure the punch is clear. Empty the tray and if there is excess paper in the punch you can clear it by sliding cardstock to loosen and remove it.

Documents Have an Unwanted Seam Along the Wire Spine

If your document is presenting a visible seam on the outside of the document, the document has likely been incorrectly bound. To prevent this from occurring place the last page of the document at the front / on the top of the book when binding it. Once bound you can turn the back page to its desired positioning, leaving the seam hidden between the second-to-last and last page.

Wire Binder Is Failing to Punch Through Paper

If your wire binder simply isn’t punching paper there are two likely causes; you are attempting to punch too much paper at once, or the wire binders punching pins are dull. If the issue is that you are attempting to punch too much paper, punching your documents in smaller stacks should resolve the problem. If you find this is reducing your productivity you may wish to invest in a wire binder which can punch through larger quantities at once such as the Renz SRW 360 manual wire binder which can punch up to 25 sheets per cycle. As for dull pins, some brands offer replacement pins and they can typically be installed by yourself at home.

If you come across any of the issues discussed in this guide, be sure to make the recommended checks to identify the cause of the issue. All of these issues occur with wire binders from time to time, but they are easily resolved once you have identified the cause of the problem. However, to minimise the risk of problems you should always invest in a high-quality wire binder. Top brands such as Renz, GBC and JBI all offer some fantastic and affordable binding machines from the Renz SRW360 ComfortPlus which is an ideal electric option for the office, to a GBC Magnapunch Pro which will punch effortlessly all day long.