Multigraf Touchline CPC375

Multigraf Touchline CPC375

Description

Multigraf Touchline CPC375 – Creasing, Perforating & Cutting Machine

Price: Contact for pricing

Location: Glendale

Availability: In stock

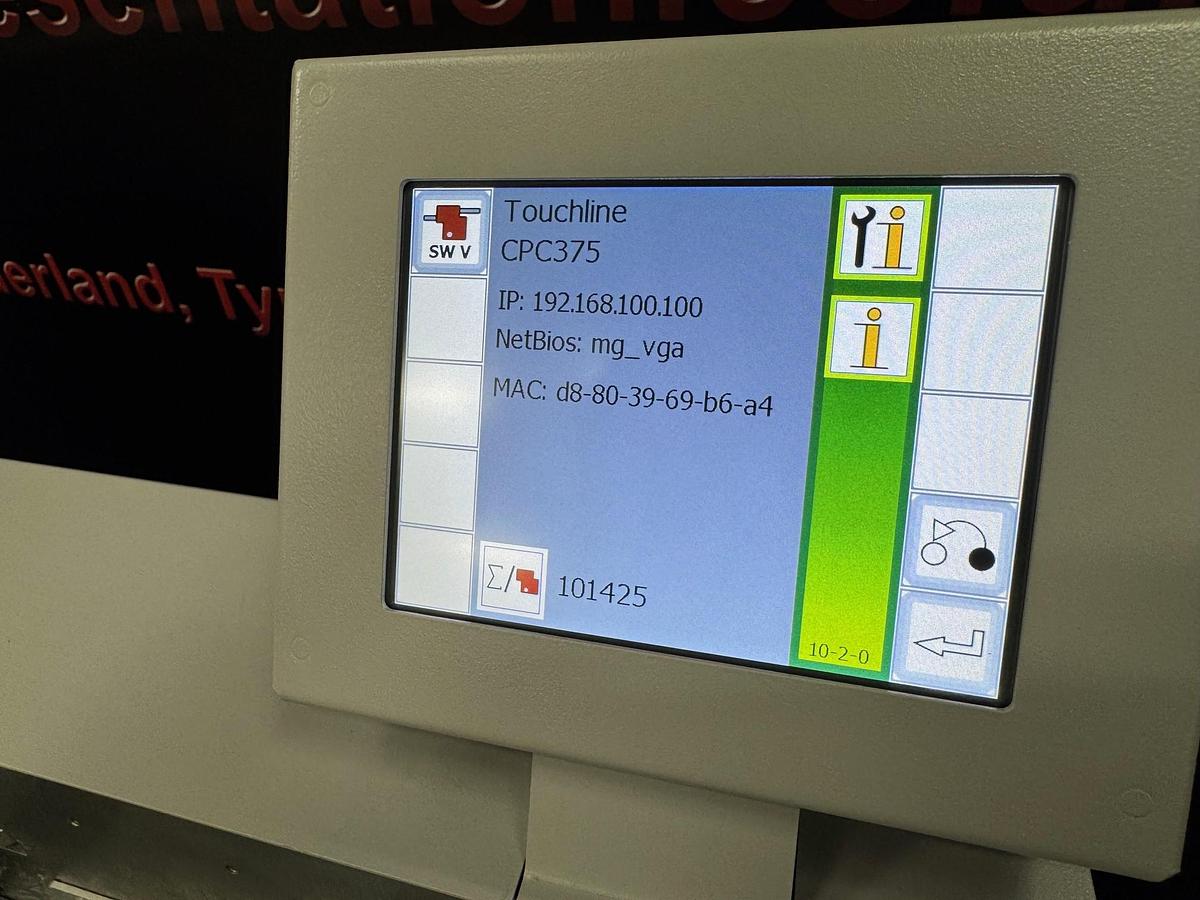

Condition: Refurbished and fully tested – excellent condition, very low sheet count

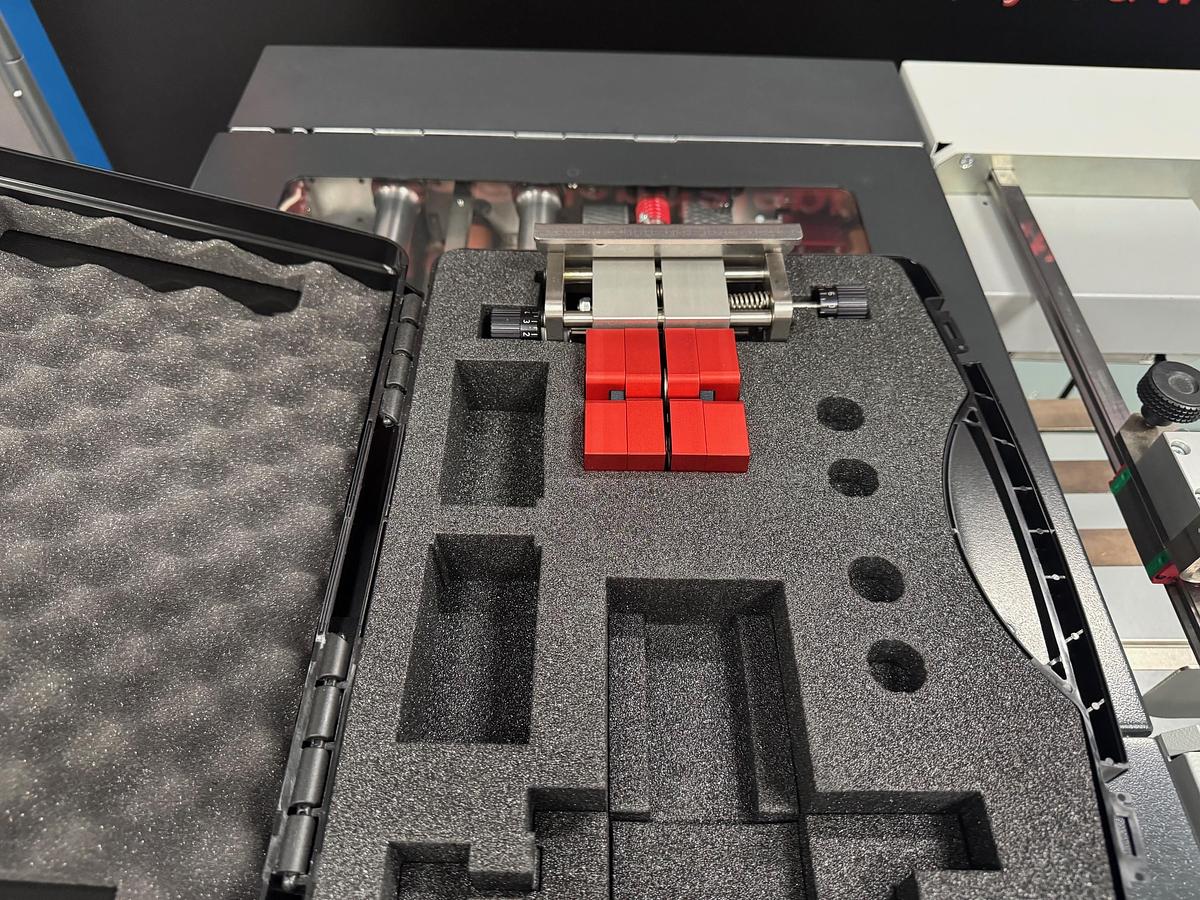

Includes: Optional start/stop perforation unit for length of sheet. Up to four can be added.

Overview

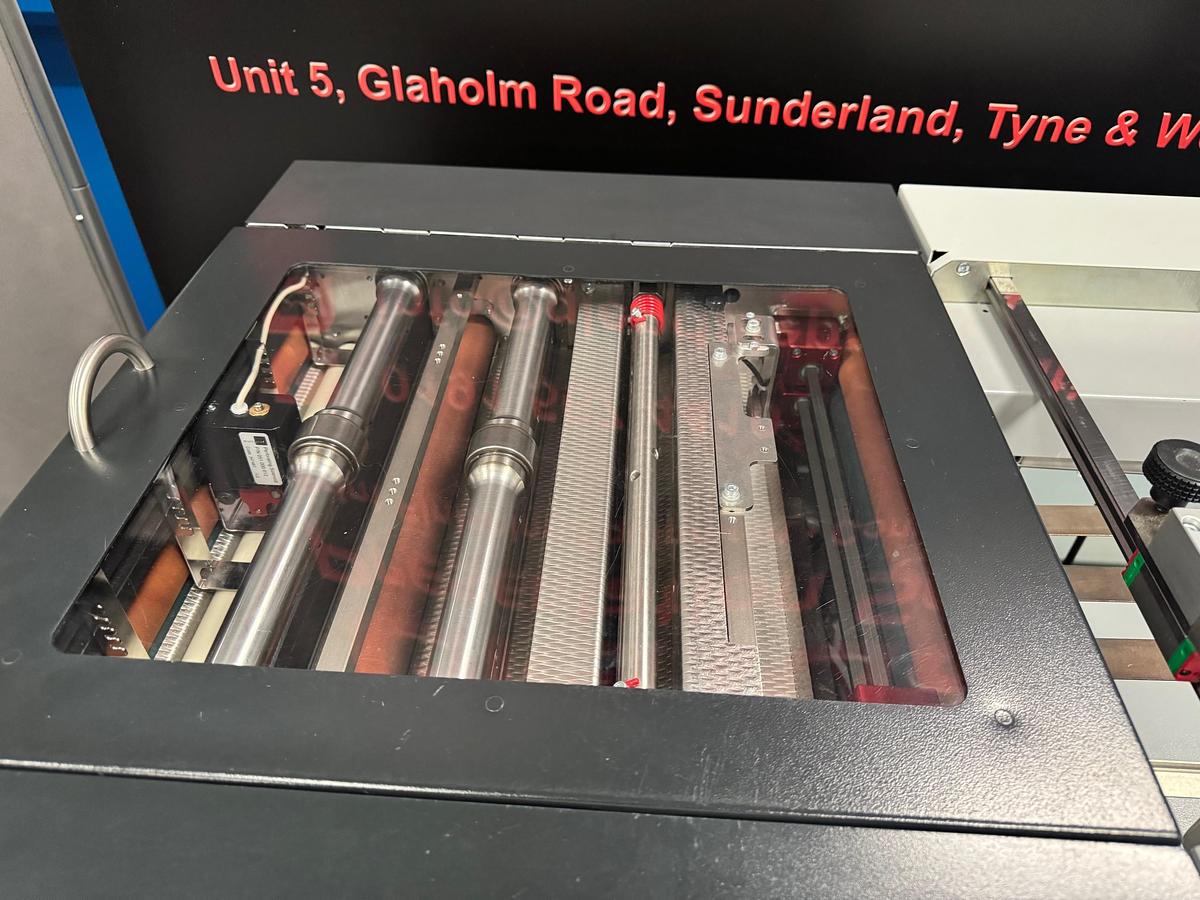

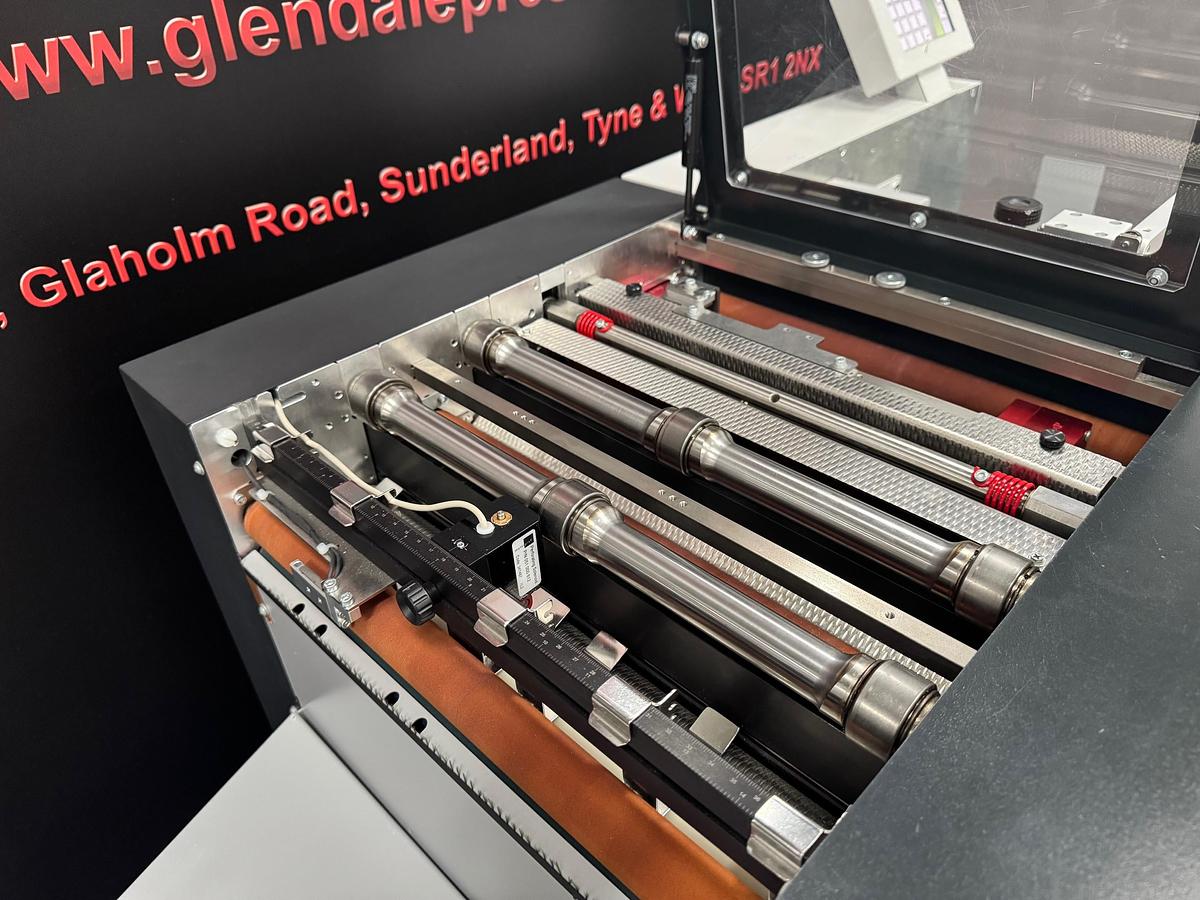

The Touchline CPC375 is a high-performance, multifunction finishing system capable of cutting, creasing, and perforating in both lengthways and crossways directions. Designed for digital printers, in-plants, and commercial finishing operations, the CPC375 delivers professional-quality output with minimal setup time. Its automated tool detection and patented changeover unit allow quick adjustments, enabling fast production of vouchers, tickets, coupons, reply cards, and other print products. With support for a wide range of paper stocks and automated operations via a touchscreen interface, the CPC375 combines speed, accuracy, and versatility in a single, compact system.

Key Features of the Touchline CPC375

- Multi-functional finishing: Cut, crease (positive & negative), and perforate (stop or continuous) in a single pass.

- Wide paper range: 80–400gsm for cutting/creasing; perforates up to 300gsm.

- Automated setup: Patented changeover unit allows quick, tool-free swaps; tools detected electronically, and working depth automatically adjusted via touchscreen.

- Flexible tooling: Dual tool module, cross knife, and lateral rotating longitudinal knives; stores up to three additional tools; up to four perforating heads for length of sheet perforation.

- High-speed operation: Up to 6,000 sheets per hour, with high-capacity feed load.

- Large sheet capacity: Maximum sheet size 370mm × 1200mm with table extension.

- Vacuum conveyor feeder: Supports offline or inline feeding from printers.

- Touchscreen control: Intuitive interface for easy job setup, adjustments, and monitoring.

Complete System Includes

- Touchline CPC375 finisher with crease, perf and cut – refurbished and fully tested

- One optional start/stop perforation unit for length of sheet perforation

- Touchscreen interface for full control and automated adjustments

- Tool magazine with storage for multiple tools

- Vacuum conveyor for reliable sheet feeding

Why Choose the Touchline CPC375?

- Versatility: Crease, perforate, and cut multiple paper stocks in one machine.

- Accuracy: Automatic tool detection and setup ensure precise finishing every time.

- Ease of operation: Touchscreen interface with quick setup reduces training and changeover time.

- Productivity: High-speed operation and large sheet capacity handle small and high-volume jobs with ease.

- Professional results: Produces high-quality output for tickets, vouchers, coupons, cards, and other printed materials.

Why Buy from Glendale?

- Professionally refurbished and fully tested – every system is serviced by our trained engineers.

- Expert training and ongoing support – we ensure you get the best results from your equipment.

- Competitive pricing on consumables – keep your finishing costs low with affordable supplies.

- Trusted supplier – years of experience in print finishing solutions with both new and used equipment.

Specifications

| Manufacturer | Multigraf |

| Model | Touchline CPC375 |

| Condition | Refurbished |

| Stock Number | 114963 |

| Min sheet size | 105mm x 148mm |

| Max sheet size | 370mm x 1200mm with extension |

| Creasing paper weight | 80gsm to 400gsm or 0.4mm |

| Perforating paper weight | 80gsm to 300gsm or 0.3mm |

| Cutting paper weight | 80gsm to 400gsm or 0.4mm |

| Feeder system | Suction feed |

| Control panel | Touchscreen |

| Double sheet detection | Ultrasonic (standard) |

| Max number of creases/perfs | 20 per sheet |

| Possible cuts | Front 4-120mm. Centre 4-40mm. End 4-27mm |

| Standard tooling | 1 crease bar (2 crease widths), 1 cross perforation tool (11 tpi) |

| Optional tooling | Stop/Start rotary perforation. 1 unit included. Option to add 4 in total |

| Electrical requirements | 240v 50/60Hz |

| Machine weight | 245kg |

| Dimensions | (L)1800mm x (W)600mm x (H)1200mm |