Intec SC7800 Pro‑RS XL

Intec SC7800 Pro‑RS XL

Description

Morgana / ColorCut SC7800 Pro‑RS XL Digital Die‑Cutter & Creaser

Overview

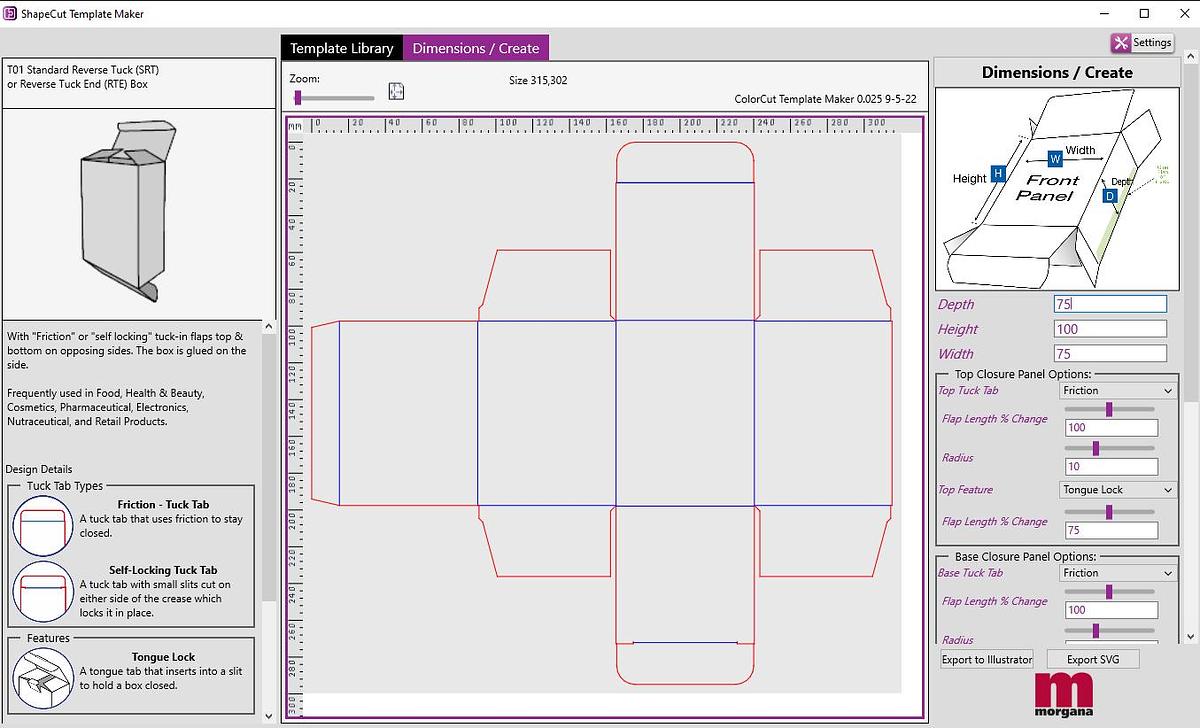

The Morgana / ColorCut SC7800 Pro‑RS XL is a market‑leading digital die‑cutting and creasing system, designed to bring high‑performance finishing in‑house. Built around a hybrid of flatbed, sheet‑fed, tangential and contour cutting technologies, this advanced system delivers precision cutting, superior creasing and automatic workflow — ideal for POS, packaging, labels and custom print production directly from your pre‑printed artwork.

Combining reliable automatic feeding with QR code job recall, high-speed cutting, and a unique dual-tool tangential creasing mechanism, the SC7800 Pro‑RS XL is engineered for productivity and unattended operation. Capable of handling a wide range of media — from standard stocks to heavier boards up to 450 microns — this unit ensures fast turnaround without sacrificing quality.

Key Features

• Digital cut-through any shape — up to 450 micron media at speeds up to 1,060 mm/sec

• No dies required — reduce cost and eliminate tooling delays

• Automatic feeder holds up to 900 sheets (max 520 × 740 mm) with self-centring and air blade separation

• QR code/Job Library recalls cut jobs automatically, even with mixed stacks

• SmartMark registration delivers exceptional cutting accuracy via included ColorCut Pro software

• Retractable media tray plus built-in media storage

Performance & Productivity

• Triple tool head: passive drag cut plus two active tangential crease wheels (male & female) for outstanding finish quality

• Vision3 CCD camera reads registration marks and instantly retrieves associated cut paths on every sheet

• Processes mixed jobs sequentially without intervention

• Quad “Grip and Drive” feeding holds media stable for accurate edge-to-edge cutting

• SmartTags hold pieces in place during cutting, resulting in neat stacks of finished sheets

• HELD mode for standalone production — load from USB and cut without a PC connection

Feed & Media Handling

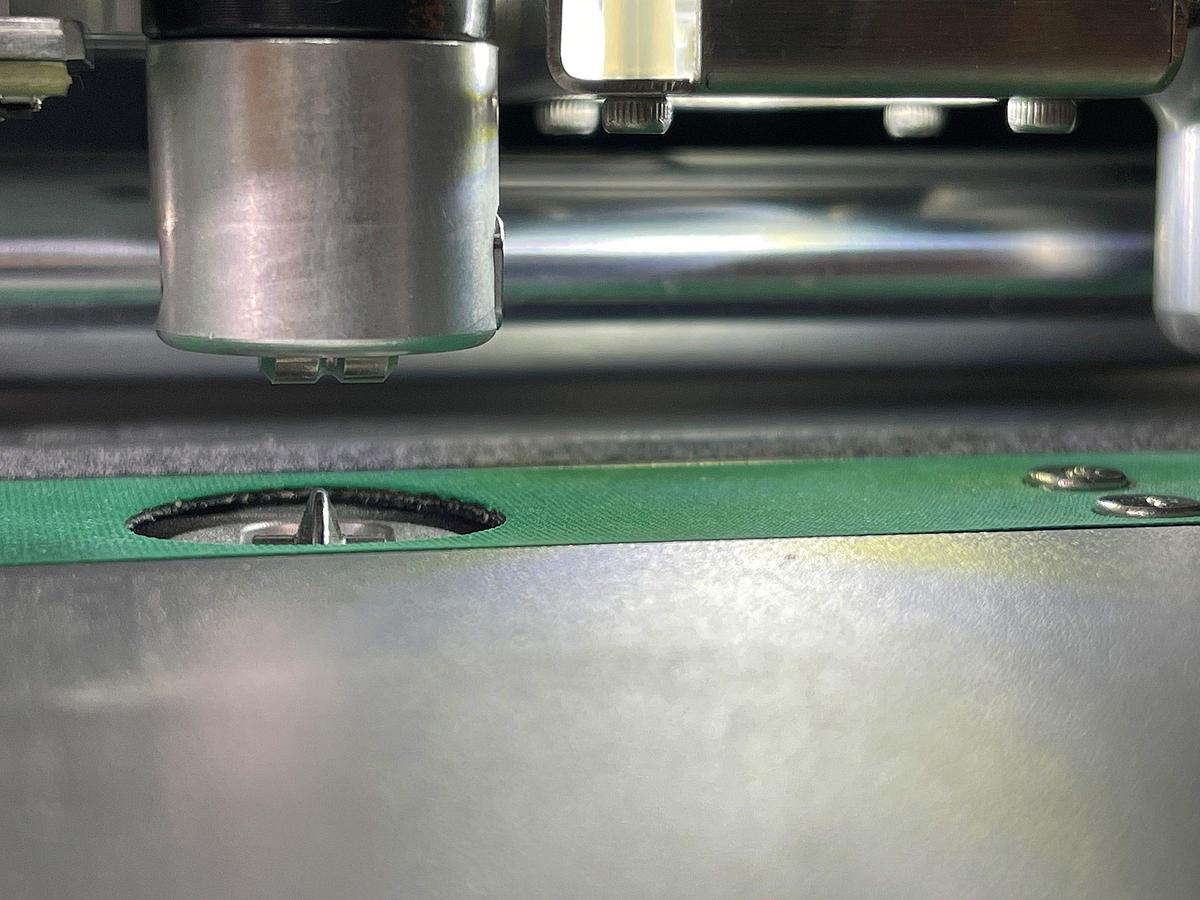

Engineered for unattended production, the auto feeder is optimised for consistent pick-up, even with laminated or curled media. A dual-air blade system works with a vacuum feed belt and separation fingers to ensure only one sheet feeds at a time, while a brief jog against the rear stop helps guarantee accurate sheet entry into the cutting system.

Precision Cutting & Creasing

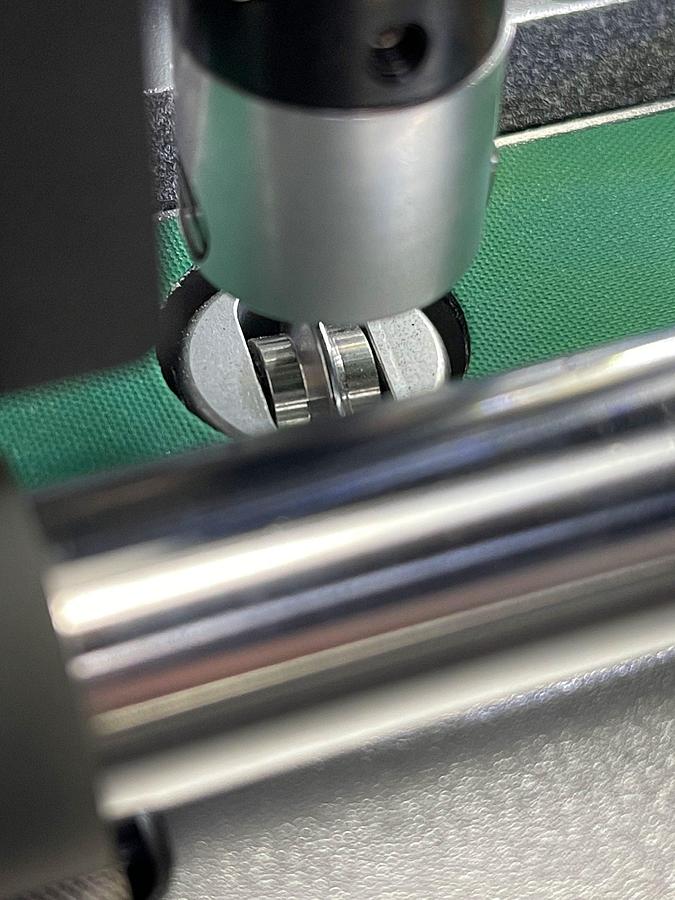

The patented digital triple-tool head offers cutting, creasing and perforation with precise control over force, speed and application from the included ColorCut Pro 5 software. Dual opposing tangential creasing creates traditional male/female style creases delivering smoother, more defined folds on heavy stocks.

User Experience & Ergonomics

• Large 7″ immersive touchscreen with live camera preview and Info-Control system

• Extensive auto-feeder controls for specialised media handling or throughput optimisation

• Adjustable touchscreen angle for operator comfort

• Handy slide-away media catch tray for space-saving operation

• Mobile stand for easy placement in any work environment

Optional: ColorCut Pro Server Station

For advanced workflow automation, the ColorCut Pro Server Station significantly enhances production productivity. Supplied with a pre-installed Windows© PC, ColorCut Pro software suite, flat screen monitor, mouse, keyboard, and software licences for two additional seats, the Server Station centralises control and streamlines your operations.

Key Benefits:

• Production Studio — core cutter application for job setup, tool control, speed, force, and cut/crease/perf settings, with instant QR code retrieval from printed sheets

• Job Library Manager — networked library management for custom job naming, searching, viewing, and assigning unique actions to QR codes or job numbers

• Centralised, synchronised source for all ColorCut users, acting like a RIP workflow to manage high-volume and mixed-job production efficiently

The Server Station allows operators and designers to save jobs centrally, recall automatically, and manage multiple cutter stations seamlessly — a significant productivity boost for busy production environments.

Why Choose the SC7800 Pro‑RS XL

• Powerful, flexible system for digital finishing — from short runs to high volumes

• Automatic job recall and intelligent feeding for unattended processing

• Outstanding cut and crease quality across a variety of media

• Designed to enhance productivity and workflow efficiency in print-to-finish environments

Contact us today to ask for sample pack or to discuss a demonstration.

Specifications

| Manufacturer | Intec |

| Model | SC7800 Pro‑RS XL |

| Condition | New |

| Stock Number | 114976 |

| Max media size | 520mm x 740mm |

| Effective contour cutting area | 510mm x 720mm |

| Crease capabilty | Reverse size capable. Dual opposing Tangential Creasing Wheel & Groove delivering up to 2.5kg (2500gf) for max 450micron |

| Auto sheet feeder capacity | 105mm and 30kg weight |

| Type of cutting | 105mm and 30kg weight |

| Max speed | 1060mm per second |

| Electrical requirements | 240v 50/60hz |

| Machine weight | 195kg |

| Dimensions | L 1013mm x D 860mm/1680mm (with Media tray)x H 1256mm |